Metal fabrication services are often used in industrial settings because they help produce high-quality pieces of equipment. While many people think of machines and components when they hear the term metal fabrication, it’s important to know that this also refers to tools that we use every day and objects that have an aesthetic value as well.

One common metal fabrication tool is the hinge, and there are several different kinds available depending on your needs and preferences. This article covers 8 of the most popular types of hinges in metal fabrication services, so you can choose the best option when you need to upgrade or replace your current hinges.

Metal fabrication services are an important part of any business

These services provide a wide range of products and services that are vital to many industries, including transportation, manufacturing, construction, and more. With these products and services comes an equally diverse set of metal fabrication supplies that allow businesses to meet their needs.

In addition to creating custom projects for a wide range of customers, many companies also provide metal fabrication services. These types of companies often offer such items as hinges, bolts, nuts, and washers – all important parts in any metal fabrication project.

1) Butterfly hinges

Butterfly hinges are among one of the most common types of spring hinges because they’re easy to manufacture and fairly inexpensive. Butterfly hinges, also known as coffin or butterfly hinges, offer an affordable alternative to standard butt hinges with a wide variety of applications.

They are usually thinner than butt hinges and don’t require as much clearance behind mounting flanges, making them perfect for cabinet doors when there is little room between wall framing members.

Due to their thinness, butterfly hinges are commonly used on heavy-duty industrial hinged panels that can accommodate their relatively low weight capacity. Each hinge consists of two parts: a fixed blade and a moving blade connected by springs that allow each blade to half its motion independently of the other.

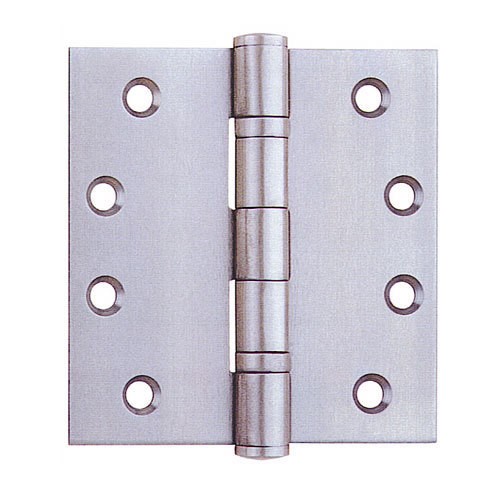

2) Butt hinges

As their name implies, butt hinges are designed to join two pieces of wood at 90 degrees. These are commonly used for doors and drawers. Butt hinges come in a variety of styles, but all work on a simple pin-and-tumbler design: The short vertical pin protruding from one door frame slides into a socket (the tumbler) on the other frame.

Some butt hinges also have flexible joints that allow you to adjust them. Steel is widely used for these applications because it has both strength and flexibility; stainless steel is often preferred in situations where water or moisture could be an issue. Butt hinges can also be made of brass, copper or plastics like nylon or ABS.

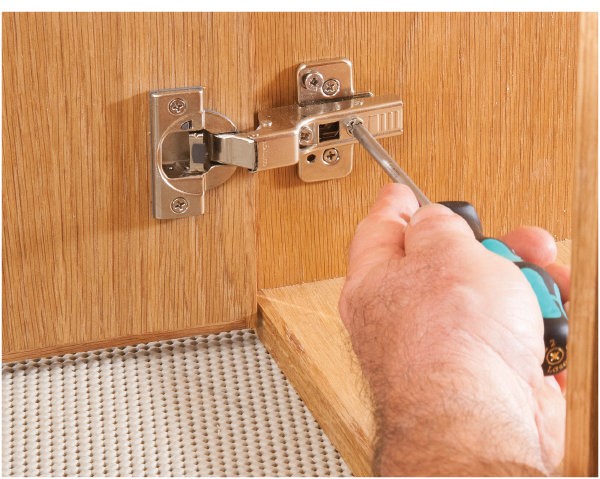

3) Concealed hinges

Concealed hinges are probably what you’re picturing when you think of a hinge. They’re common on doors and cabinets since they tend to be flush with whatever surface they’re mounted to. Concealed hinges don’t just swing out from an object (like you may think); their mechanism is contained within the frame and body they’re attached to.

This means that, like other kinds of hinges, concealed ones can be used for pulling or pushing movement. But due to how hidden their moving parts are, concealed hinges appear much sleeker than other types of hinging devices. A truly concealable hinge shouldn’t add any bulk or depth to its parent piece—but if it does, it won’t detract too much from its overall design.

4) Continuous hinges

A continuous hinge is a special type of hinge designed to accommodate large, sometimes irregularly shaped or curved panels. These hinges can be operated by hand and have no part that swings around, making them ideal for applications such as wooden doors or gates.

Continuous hinges are typically used when there isn’t sufficient space to install standard butt hinges. When you need a hinge without an offset, continuous hinges are your best option.

Typically available in satin brass, galvanized steel, and stainless steel finishes. Despite their name, swing-type closet door hinges provide much more than simply swinging movement.

5) Cup hinges

Cup hinges are considered one of the most versatile hinges as they can be applied to just about any door regardless of its weight. They are extremely durable and may last a lifetime if properly taken care of. These hinges should not be used on doors that swing more than 180 degrees, since their unique design makes them vulnerable to wear and tear.

6) Spring loaded hinges

Spring-loaded hinges, also called torsion hinges, use an internal spring to keep a door securely shut. The advantage to these types of hinges is that they can be extremely strong, although they do have a few downsides. For example, if too much force is applied to open them or if it’s windy outside you may find that your door blows open as a result of all that pressure being put on one side only.

If you are looking for security and strength, however, then you will love how well spring-loaded hinges work. Another downside is that they tend to make a lot of noise when opening because of all that torque working inside. If used sparingly though this hinge will last for years without fail and are highly resistant to corrosion and rust.

7) Sliding door bottom rollers

Sliding doors are one of those things that you don’t think about until something goes wrong. The most common problems people face with these doors are alignment and breakage, both of which can be solved through sliding door bottom rollers. With your rolling system in place, you can also add a custom door sweep to ensure that air doesn’t get trapped on your sides and behind your door.

Non-slip self-closing hinges: A non-slip self-closing hinge is exactly what it sounds like – a new type of hinge for your cupboard doors or kitchen cabinets designed to keep doors from slipping open accidentally. They work by helping your cabinet door sit tight against its companion during use so it won’t fall off because an old hinge loosened or was removed altogether.

8) Stainless steel kitchen cabinets with ball bearing slides

A kitchen cabinet with ball bearing slides is an example of a high-quality ball bearing slide. This type has specially designed tracks or grooves to allow for smooth opening and closing without binding. Ball-bearing slides are common in kitchen cabinets because they’re usually under constant use; it’s critical that they don’t bind and limit access to your kitchen.

Another advantage is that ball bearing slides have fewer moving parts than other hinges, which means less maintenance over time. However, you should keep in mind that although ball-bearing slides can support heavy loads, they shouldn’t be used on cabinets above seven feet tall. For larger cabinets taller than seven feet, consider using other types of hinge mechanisms.

Tips for choosing hinges based on your needs

Most hinges are going to be found on doors, either interior or exterior. You can buy pre-hung door sets, which include all hardware, but they aren’t always ideal. If you’re planning to build your own doors, consider buying non-prehung kits and picking out your own hinges (based on style and color preferences).

Non-prehung kits can save a lot of money. And if you do plan to work with them, make sure that you have sufficient clearance space so that you can close your doors completely. This depends entirely on how wide each half of your hinge is relative to how far apart it needs to fit in order for its job to get done properly. Another decision is whether or not your hinges will be visible from one side or both sides.

It might seem like an insignificant detail, but even if you only intend to install the hinges once and forget about them, installation can come back to haunt you over time; being able to see what you’re working with beforehand helps ensure that everything comes together correctly.