What are your freight and container shipping concerns? Or is it the case that you require information about the best practices for towing and moving objects or vehicles? While different factors contribute to having a seamless towing/moving experience, the choice of your trailer winch strap is a crucial factor within the lot.

In this article, learn about the rudiments of the trailer winch strap, its maintenance tips, and factors to consider when making a purchase choice.

What is a Trailer Winch Strap?

A trailer winch strap is a piece of towing equipment that combines the strength of a woven rope and a strong metal hook for on-loading, offloading, and towing purposes. Although in some cases the winch strap does not come with a hook (it is bought separately), it requires a hook for operation.

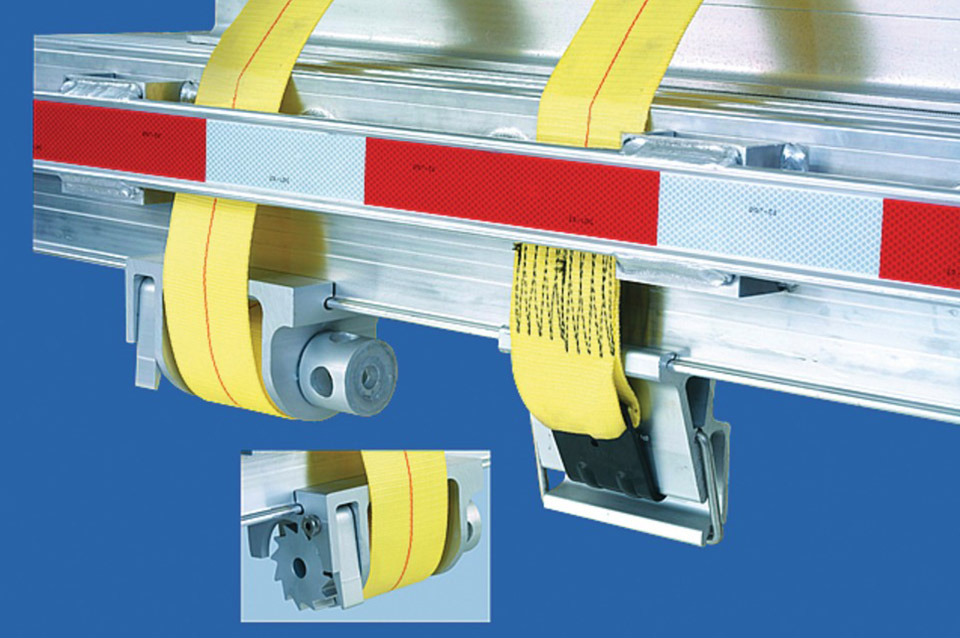

The trailer winch consists of several parts including the strap, hook, drum, and some others. While the primary use of a winch is pulling, it has found utility in different forms. It can be used to pull up a boat, tow a damaged vehicle, or load onto or off a trailer.

It is an essential part of logistics and freight. Once the winch hook is attached to the boat, the truck, or the trailer, the winch drum controls the length of the strap, hence pulling the concerned object or vehicle. Trailer winches can either be manually operated or electrically operated.

How to Select a Winch Strap

Several factors are necessary for consideration when determining the winch strap to buy. But one important factor is the weight of the object being towed or moved. Different weights require different winch capacities. However, the trick is to use a winch with 1.5 times the capacity of the item you are towing.

Another factor to consider is the width and length of the strap. Winch straps come in different widths and length specifications. This is for easy adaptability to the coverage needs of the load and the grip requirements of the different loads/vehicles.

The standard rule for determining the ideal strap length is to get the exact winching distance required for loading onto the trailer or a length that is longer than this winching distance. You can achieve this by measuring the distance between the winch mount and the end of the bunks (in the case of boat trailer winches).

Generally, one of the best options for multi-use straps is suited to the needs of the heaviest and largest trailers. With these, users can rest assured that their winch can meet a wide range of needs. Therefore, the specification for an ideal trailer winch is 3″ strap width, 30″ strap length, 3″ Delta Ring, 3/8″ Hook, 18″ Chain Assembly length, 5000 Lbs capacity, and 15000 lbs breaking strength.

Secondary to the aforementioned factors are the webbing, the end fittings, the sewing pattern, and the ratings and markings of the strap. While the first category of factors speaks to the capacity of the strap, the latter addresses the quality of the strap and the longevity it promises.

Maintenance Tips for the Winch Strap

The quality of your trailer winch strap goes a long way in determining the quality of your on loading, offloading, or towing experience. To ensure the longevity of your strap, first, you must pay attention during the purchase process to be sure you are buying the best quality strap. Then adopt routine maintenance checks for weakened stitches or frays.

Some routine maintenance tips include:

- Lubricate the cable once a year.

- Ensure that you spray the shaft and the cable.

- Remove the winch cover and lubricate the gears. Only use lithium-base grease annually.

- Do not grease the clutch lining.

- Prevent overheating with the use of an appropriate circuit breaker.

- Stay far away from a weak winch when in use. A break in the cable could result in serious injuries.

- Do not use the winch as permanent support for the load. Detach the winch cable hook from the bow eye when not in use. It is designed for temporary support.

There is no doubt that good maintenance elongates the shelf life of the strap, but there would always come a time when your strap must give way to a new one. Frayed stitches, faded colors, stains, and tears are some indications of the need for a replacement.

Waiting for worse signs or the actual dismemberment of the trailer winch strap may cost you more than pro-activeness would have. The procedure for replacing the strap is quite simple and easy. All that is required is a utility knife for cutting old strap webs, the box wrenches for the anchor bolt, and a new bolt just in case the old one is bad.

To replace your winch strap, first determine the right strap for the winch. This is dependent on the working load capacity, strength, and weight of both the winch and boat. The replacement procedure involves the following steps:

- Remove the old winch strap from the winch drum.

- Loosen the locknut in the drum and replace it if necessary.

- Attach the new winch strap through the bolt.

- Roll in the new strap into the winch drum neatly.

- Finally, attach the new strap to the boat’s bow.

There has been a debate as to the perfect positioning of the winch strap. Different people have come up with various opinions of what obtains. So the question is- ‘Should the winch strap go over or under the winch drum?’

The truth is that in many cases, it does not matter. The angle from which the strap winds over the drum does not affect the effectiveness of the strap. Whether clockwise or not, the strap does its work provided that the bow eye is pulled in a flatly horizontal position without a downward or upward lift. The more important worry is to have the winch at its required height. Once this is in place, nothing else should matter.

However, cheap winches have a design that gives room to only clockwise winding and hence will not maximize output in an anticlockwise position. Check the quality of your winch to determine its required position.